Vognen din er tom Fortsette å handle

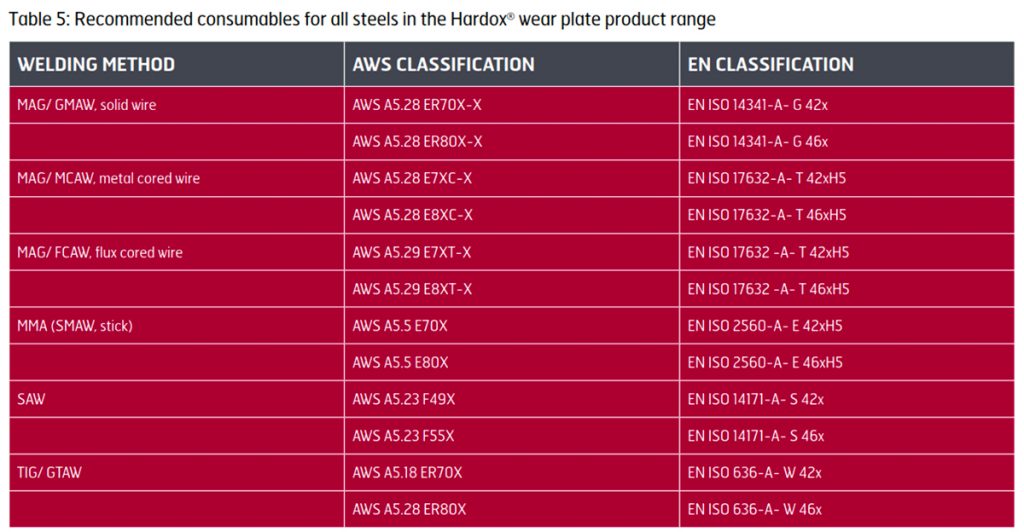

Recommended consumables for Hardox 500

- Max. yield strength of consumable (all weld metal) 500 MPa.

- Diffusible hydrogen content of consumable should not exceed 5 ml/100 g weld metal (H5)

- Make sure that consumable are stored and handled according to the consumable manufacturer recommendations

- Tack welding with stainless steel consumables (AWS 307) could be performed in room temperature if necessary.

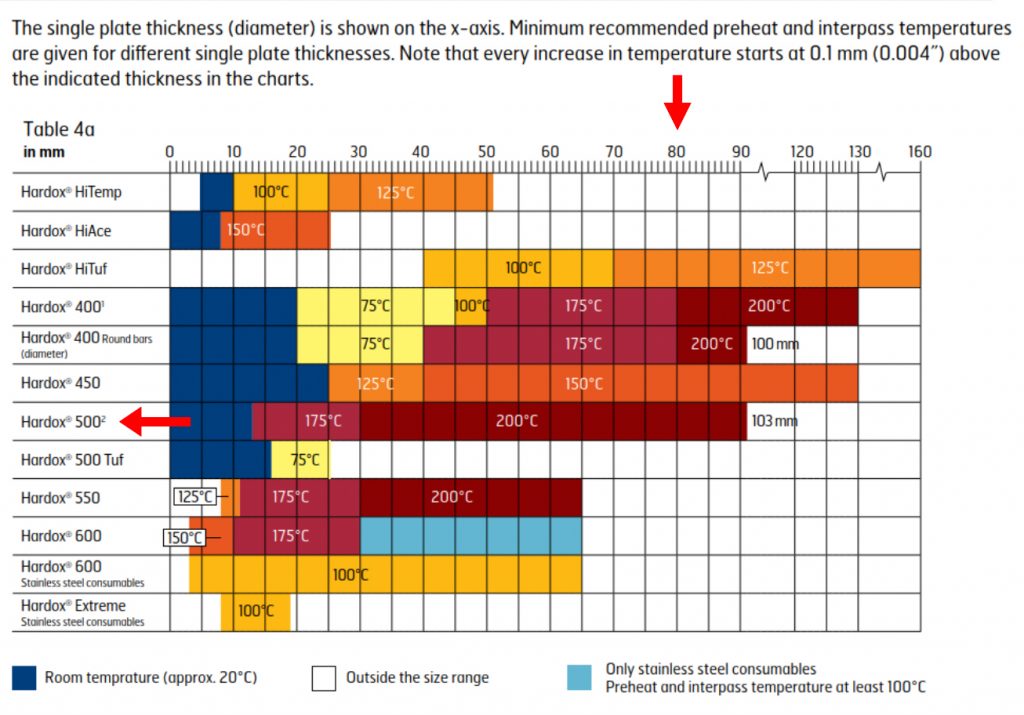

Recommended preheating temperatures for Hardox 500

- Recommended preheating temperature for Hardox 500,

t=50 and 80 mm is 200 °C - Max interpass temperature is 225 °C

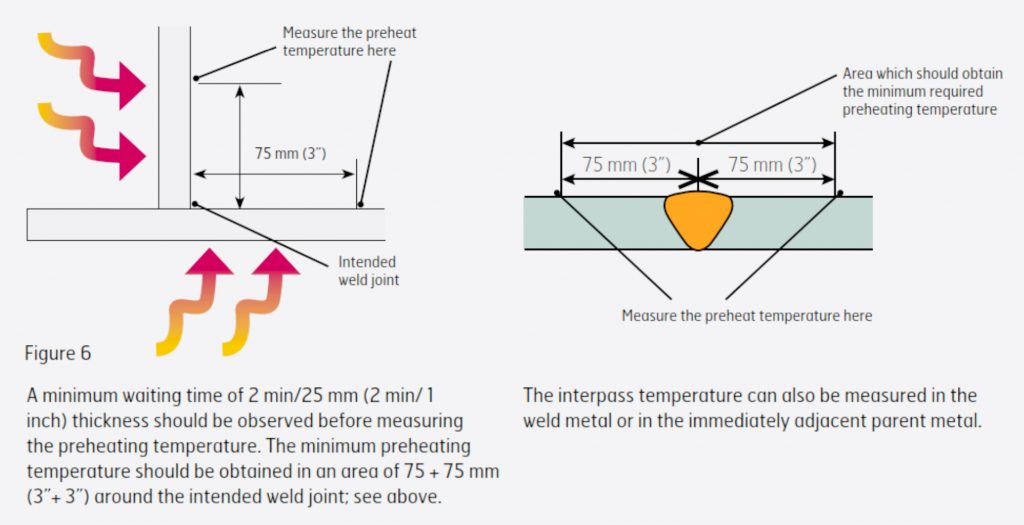

- Preheating is usually conducted with either electrical mats or an open oxy fuel flame. Do not overheat the base material (risk for annealing of the material).

Preheating process

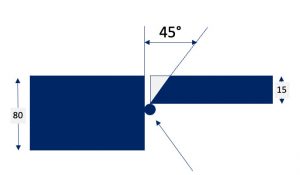

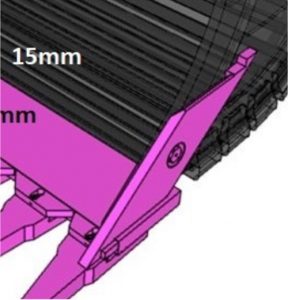

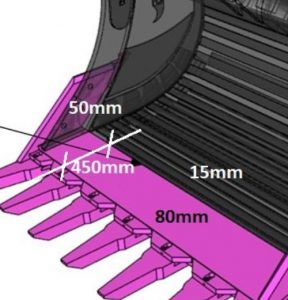

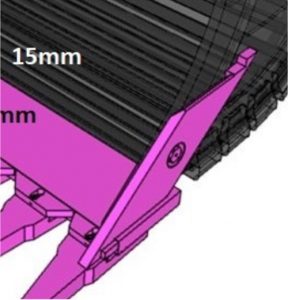

Welding of ”cut edge”plate, Hx 500, t=80 mm

Start the weld sequence from the central part of the cut edge and weld towards the sides. This should be done alternately towards the both sides and with the start point at different locations of the weld length.

Welding sequence

- Recommended preheating temperature for Hardox 500,

t=50 and 80 mm is 200 °C - Max interpass temperature is 225 °C

- Preheating is usually conducted with either electrical mats or an open oxy fuel flame. Do not overheat the base material (risk for annealing of the material).

General information

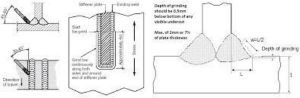

- Avoid any start and stops at corners, see fig 01

- Use a rotating grinder to grind the weld toe (transition in-between the weld metal and base material) at highly fatigue exposed areas.

Fig 01: Fish tail technique provides 5 times higher fatigue strength.

Weld around the corner of the of the front part of the side plate should be grinded smooth.Especially the weld toe area.